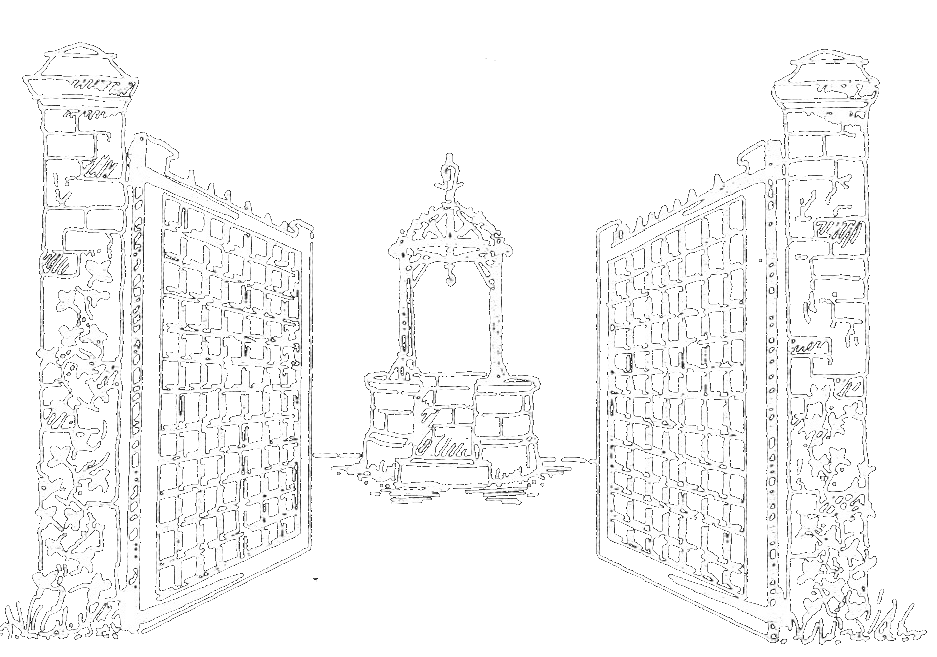

Our Process

Having been developed over 5000 years the lost wax casting method is an intricate process providing impressive detail. Used frequently in sculpting and jewellery making it enables intricate casting, showcasing master craftsmanship.

Wax moulding

Our process starts with creating a hand carved master wax model. A plastic mould is created around the original model in preparation for wax. The master wax model is removed and wax is poured into the perfect negative plastic mould. The mould is rotated to apply an even coating to desired thickness. Once dried any seams or imperfections are chased with a hot tool.

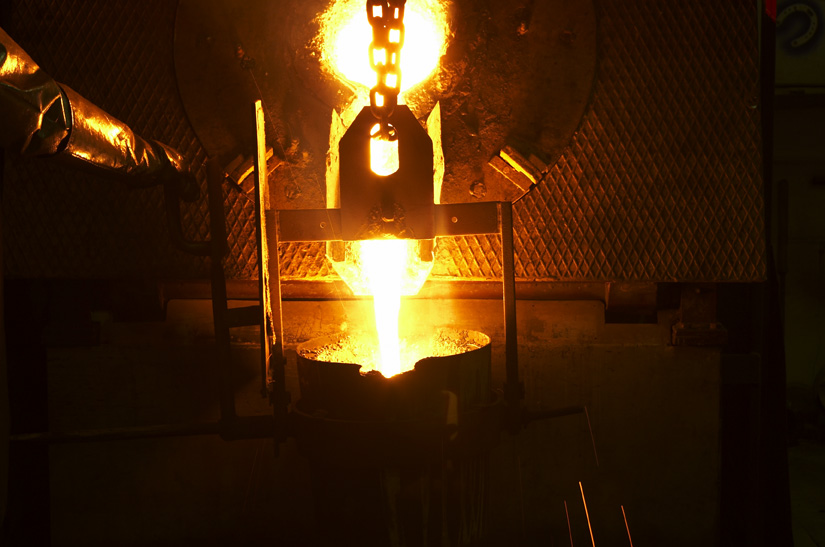

Casting

The wax mould is then coated repeatedly in an engineered material creating a thick hard shell. Once dried the wax is melted out of the interior via kiln drying. Molten Brass is then poured into the hard shell. Next the hard coating is removed and any imperfections are metal chased. Finally each product is hand polished.